By Adam West, Course and Curriculum Manager at CriticalPoint

Stop me if you’ve heard this one. The 30-Minute Rule: “You must wait 30 minutes before you can resume compounding if your PEC is shut down for any reason.” Even though the 2008 version of USP <797> listed this as a recommended policy (disappearing with the 2019 proposed revision), the amount of external and internal training content along with the number of conference presentations still teaching this 30-minute rule is surprising to me.

Just like when our parents told us we had to wait 30 minutes after eating to swim, and then we told our kids the same thing… This is how myths are created. And it still seems to be a pharmacy tradition—based on a misconception—that won’t go away because it’s “always been done this way.”

The reality is, by the time you finish reading this, you can resume compounding activity in your PEC if it is ever shut down.

Even AI Got It Wrong

Out of curiosity, I asked ChatGPT, “How long should I wait to compound if my hood was shut off?” It replied, “Per USP <797> (2024), the PEC must run for at least 30 minutes before use—unless the manufacturer says otherwise.”

I knew that wasn’t accurate. So, I fact-checked the latest <797> (just to be sure), told ChatGPT it was wrong, and it thanked me for catching the error. It explained that the 30-minute wait comes from older industry practices or manufacturer recommendations and is meant to allow time for ISO 5 conditions to be reestablished. Fair enough—but it couldn’t tell me exactly how long that actually takes.

Stick around—we’ll do the math and find out together.

What standards require the “30-minute rule”?

In previous versions of USP <797>, the 30-minute wait was a policy recommendation—but that’s no longer the case. The current version doesn’t provide guidance on how to resume compounding after a PEC shutdown. It only states that PECs should remain on at all times, except for maintenance.

Meanwhile, the Model Standards for Pharmacy Compounding of Non-hazardous Sterile Preparations (2016) for the National Association of Pharmacy Regulatory Authorities (NAPRA) still cite the previous USP <797> version, stating, “If the PEC has been turned off, it must be allowed to run for at least 30 minutes, or as recommended by the manufacturer, before cleaning, disinfection, and compounding.”

I strongly disagree—especially with waiting 30 minutes before even starting cleaning and disinfection. Fortunately for our Canadian colleagues, this can be addressed in SOPs by deferring to manufacturer-specific start-up recommendations. These times vary, but none require anything close to 30 minutes.

PEC Cleaning and Disinfection Procedures

We won’t cover specific PEC cleaning steps here, but I will point out that EPA-registered agents described in USP <797> have defined contact (dwell) times. Operators must be trained to follow effective cleaning practices, and understanding contact time is essential to that success.

When operators understand contact times, they also know how long it takes for agents to work and how much time is needed to complete the full cleaning process. On average, it takes about 5 to 8 minutes to clean and disinfect a standard 4-foot LAFW and its contents.

Do PECs have air changes per hour (ACPH)?

Of course, PECs technically have ACPH, but we don’t usually think in those terms. Our focus is on maintaining continuous HEPA-filtered airflow over critical sites, not on the rate of air changes.

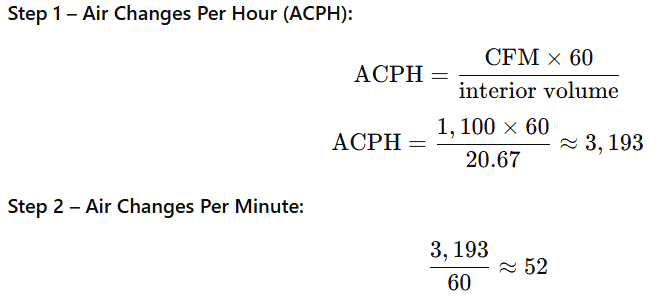

Let’s break it down: A typical 4-foot LAFW, like the NuAire NU-430, delivers around 1,100 cubic feet per minute (CFM) at 100 feet per minute (FPM). The interior workspace measures about 20.67 cubic feet, and the HEPA filter area is roughly 10.86 square feet.

That’s roughly 52 air changes per minute—nearly one complete air change every second. So yes, it’s safe to say that most PECs can reestablish ISO Class 5 conditions very quickly.

Final Thoughts

Always ask questions to understand the why behind the what. Don’t fall into the “this is how we’ve always done it” trap. Most important, there’s no magic 30-minute wait time after a PEC shutdown. By the time you’ve properly cleaned and disinfected your PEC—following all required steps, letting your final sterile IPA application dry, and adhering to your manufacturer’s specific startup and operational guidelines—you’re good to go. Sterile compounding can resume immediately once ISO 5 conditions are reestablished. Don’t wait just for tradition’s sake.

Want to view all of our blogs all in one spot? Access our entire Chronicle library here!

Learn about CriticalPoint’s product offerings!

Related Resources

The Compounding Chronicles: Are Smoke Studies Still a Thing?

The Compounding Chronicles: Outsourced Suppliers and Shortages and Tariffs, Oh My!